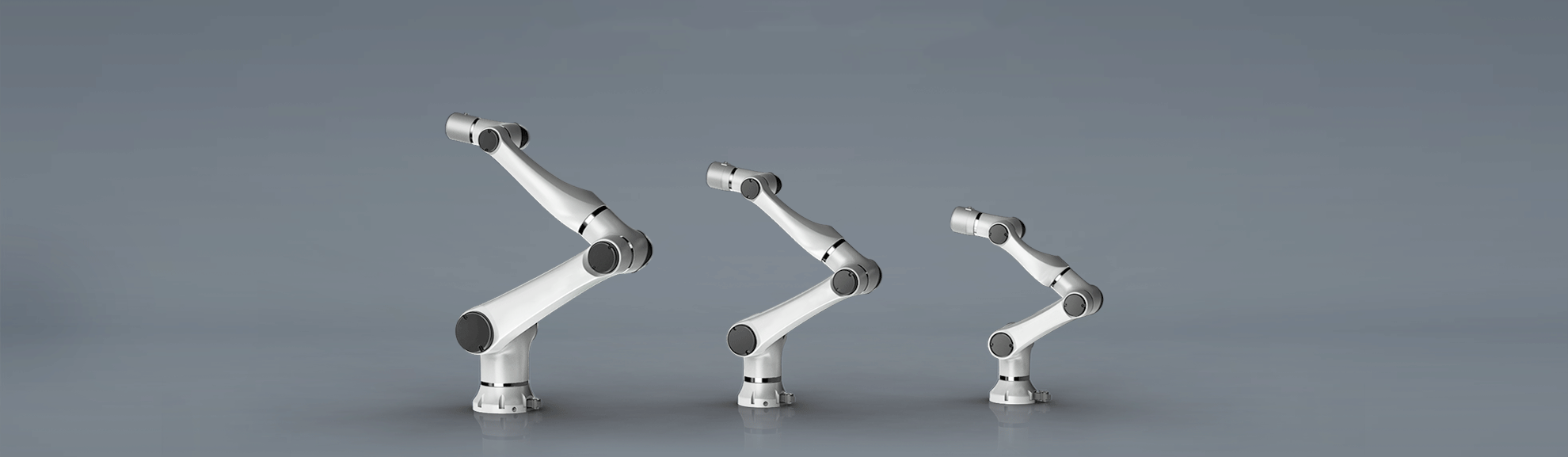

Here at Ascendze, we provide turnkey solutions using Industrial and Collaborative Robots.

Integration Partners:

Elfin

Azena

-

Welding Process

Material Handling

Manufacturing Assembly

Food & Beverage Handling

Painting

Pick & Place

Polishing

Glue Apply

Machine Parts Loading

Packaging & Palletising

-

Manufacturing

Logistic

Service Industry

Healthcare

Case Studies

-

2D & 3D Robotic Adhesive Bonding Machine

In 2015, Ascendze developed the first 2D and 3D robotic adhesive bonding machine.

Key partners: 3M, Henkel, Nordson and Polytech.

Key industries: PCBA, Semiconductor, Automotive and Aerospace.

-

Robotic Ultrasonic Cleaning Automation

Key partners: ABB Robot and Aligent Spring

Application: Cleaning of stamping parts for Ultrasonic solution

Advantages: Reduce labor, Improve cycle time by 70%, Improve safety processes

-

Robotic Stud Insert Automation

Key partner: KUKA Robot and Cameron a Schlumberger Company

Application : Robotic stud collection, stud length check, greasing and auto stud insert with location and plane search feature, selective torque setting and monitoring for stud insert

Advantages: Reduce labor, improve cycle time be 30%, improve quality of stud process, zero human assist

-

Pick and Place

F&B Industry

Robot picks trays and cups for a cafe to clear trays for tables.

-

On-The-Fly Laser Mark and QR code Scanner

6 axes robotic Laser Marker system is the 1st Solar wafer pick , laser mark and QR code scan On-The-Fly system.

It uses the Bernolli Principal for thin wafer (80 to 100micron Thickness) pick and place.

On-The-Fly laser mark with robot motion control.

Find the right option for your Pick & Place system — replace repetitive tasks with automation in any manufacturing scenario.

Widely adopted in the F&B, automotive, electronics and pharmaceuticals industries.